|

|

Vol.

26 No. 5

September-October 2004

Innovation in the Chemical Industry

The Way from Pure to Applied Chemistry

IUPAC CHEMRAWN Conferences provide an essential way for the Union to address issues that transcend pure science and have important socio-political aspects. CHEMRAWN XVI, which was held concurrently with the IUPAC Congress/General Assembly in Ottawa, Canada, was devoted to “Innovation in the Chemical Industry: The Way from Pure to Applied Chemistry.” The conference, held on 9 August 2003, was organized as a forum with three panel discussions along the following themes:

• Innovative Process and its Modalities or Enabling Radical Innovation

• Instruments of Support in the Process of Transforming Inventions into the Innovative Process or Doing Breakthrough Research

• Regulatory Problems for the Implementation of Invention or Knocking Down the Barriers to Innovation At the forum, 16 papers were presented—4 were delivered by invitees and 12 were delivered by CHEMRAWN committee members representing industry and academia. Overall 27 people participated in the forum. The summary presented here was prepared by Jerzy Kopytowski.

by J.A. Kopytowski

The goal of CHEMRAWN XVI was to examine the innovation process in the chemical industry; specifically to look at techniques for more efficient development of new products and processes, and approaches to overcoming the significant barriers encountered in these efforts. The proof that this initiative was timely and well oriented is the recent establishment in the United States of the National Innovation Initiative, which was created by the Council on Competitiveness. The previously underestimated management of the technology has become crucial for further development. Innovation is much more than invention. As presented during the forum, the process of innovation has real impact in the following dimensions:

• social—it changes society's behavior and consumption patterns

• economic—it has impact on national income and turnover of companies

• financial—it creates targets for investment

• scientific—it opens new areas of know-how by advancing our understanding of the rules of nature

Innovation also results in advanced techniques and instrumentation. Often major innovations require changes on a variety of levels:

• social—organizing people around the goals of development

• human resources—developing new ways to manage and organize human capital

• instruments—designing and engineering new instruments or envisioning new applications using existing instruments

• information technology—improving computer technology in order to collect and process large amounts of data

• economic—creating new methods to continually assess the economic impact of the innovation

There are no systematic studies analyzing and evaluating the progress achieved through innovations, including the impact of new processes on new products, or of new products on new applications. Progress is rather evaluated according to the following parameters:

• increase in the living standard at lower social cost

• development of new ways of thinking

• new frontiers of knowledge

|

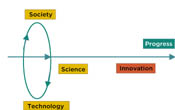

| The ternary approach—the innovation loop within the neo-cartesian rationalism, as presented by R. Hamelin. |

Until around 1975, the innovation process was ruled according to a simple linear rationalism by which scientific research impacts on technology development, and the later impacts on societal application. However, and as presented by R. Hamelin (see figure), science, technology, and society are all part of a more complex interaction, by which innovation appears as a factor of intensity depending on the three interfaces on a circular loop and progress appear as a the flux created by this intensity.

The innovation loop has several interesting features. Progress is a consequence of the intensity of the exchange between the three components (science, technology, and society). For example: a decrease in the financial support to a research activity might induce a reduction in the overall progress. Through a cooperative program, the innovative loop of a developed country might induce an innovative intensity in a less developed country creating the necessary conditions for real interaction between the three components (However, without a scientific structure there is no chance for significant progress).

|

| Innovation is not a linear process, as presented by P. Norling. |

Despite the obvious complexity, some companies are still trying to measure the impact of the innovative process by simply analyzing the number of new products introduced during a given time period. Such analyses are made without standard methodology and it is difficult to objectively judge the impact of the innovative process and even compare results from different industries. In his presentation, P.M. Norling discussed how innovation is the key to growth in the U.S. chemical industry and presented several “tools” used to encourage more innovation.

Present Character of the

Innovative Process

As A. Smith showed with his example of the United Kingdom, the restructuring of the chemical industry in the last decade was due in large measure to globalization trends. This fact has large-scale implications for research and development (R&D) and innovation in the chemical industry. Following are some of the issues surrounding globalization that speakers discussed:

• As G. Intille reported, R&D is no longer a local activity—it has worldwide components. He also pointed out that competition in the chemical industry might arise from any corner of the world.

• P.M. Norling noted that a 5% yield from R&D is fairly typical for most chemical companies (some report better than 20%). To finance such a low yield is beyond the means of small and medium-sized companies, according to Norling. Therefore, R&D has become concentrated in the multinational companies, many of which have spent more on R&D than on direct investments during the last several years.

• As reported by M. Evans, the implementation of innovations on an industrial scale requires more and more investment due to the global capacities of the industrial units. (e.g., BP Chemicals first plant of fluidized bed process for vinyl acetate monomer has a capacity of 250 000 t/year).

• As discussed by M.C. Chon, M. Imanari, M. Evans, and R.H. Jensen, a trend in the innovation process is to apply the most sophisticated computer modeling and analytical devices to speed up industrial design and implementation. This has been mainly true in areas such as reactions scaling, catalyst selection, and testing of reactor models.

• Innovations are usually related to the chemical reaction, which may be regarded as a central processing unit in the frame of the technological unit. The technological unit is also composed of process units that feed the reaction conditions, as well as process the products of the reaction into commercial form. The selection and engineering assessment of these adjacent units in the majority of cases is established mainly by the computerized systems and is not necessarily part of the innovative process.

• G. Intille pointed out that companies often rush to evaluate the cost-effectiveness of innovation, but as J.A. Kopytowski discussed, it is often necessary to apply heuristic rules to assess the size and pattern of specific units involved in the implementation of an innovative process. Regular assessments are needed for decision-making purpose, resulting in a “kill” or “continue” decision. Use of heuristic rules results in many fewer errors according to Kopytowski. Companies have developed specific rules of assessment from the point of view of algorithms (according to P.M. Norling) and supervision organization (i.e. Degussa Project Houses, presented by M. Droescher).

• It was clear from the presentations that biochemistry is dominating chemistry research. A survey of worldwide abstracts has shown that 42% are oriented toward biochemistry and 20% to applied research. In 2000, 25% of U.S. patents were related to biochemistry. However, it should not be forgotten that each bioprocess also requires unit processes defined by chemical engineering.

• Through “octopusing,” chemical processes are being applied in other industries and are being used to develop new products outside the “classic” chemical industry. The examples given by F. Kuznietsov showed the amazing applications of advanced chemistry and physico-chemistry in the fields of energy production and distribution. It is expected that this trend will lead to the establishment of new scientific disciplines.

• There are growing numbers of qualified chemists worldwide who are outside of the traditional research centers of the industrialized countries and who can't find jobs at universities because they are already staffed beyond capacity. However, as P. Moyna discussed, the technological changes that are occurring throughout the industry are requiring new development strategies, which should provide new options for research chemists in these areas.

| Research and Development has the task of kissing 100 frogs in order to get 1 prince.

Therefore . . .

• go for the ponds with the highest potential for frogs

— have the right strategy

• let enough people kiss a limited number of frogs

• keep the focus and balance resources

• kiss the frogs skillfully and creatively

— apply the most modern techniques

and interdisciplinary teams

• avoid double kissing

— use available information

• kill the unsuccessful frogs as early as possible

— manage projects with go/exit milestones |

|

Identified Deficiencies in the Innovative Process

CHEMRAWN XVI explored the external and internal deficiencies of the innovative process in the chemical industry. The external deficiencies discussed were as follows:

• The introduction of biotechnology into many processes has resulted in a new impact on the environment that requires large capital expenditures to sustain conditions of operation and commercialization or require changes to laws or rules.

• The new processes used in the chemical industry are of higher capacity and automated, which means that less labor is required and fewer workers are needed.

• The R&D process is concentrated in the large multinational chemical companies. While small- and medium-sized chemical companies provide about 90% of the employment, they are mostly excluded from the innovation process.

• In many countries, young people are avoiding scientific careers, especially in the chemical sciences, because there is a lack of jobs for scientists. The establishment of “technology parks” has been explored as a means of facilitating interaction between academia and industry and generating interest in scientific careers.

• Government attitudes and funding are mostly inadequate. In the United States and the European Union, government funding of R&D exceeds the gross domestic product (GDP) of many countries. Therefore, one could expect that these funds would be distributed wisely and in conformity with the merits of the projects. However, many problems have been identified with the way R&D funds are distributed:

—Funds are going mainly to the “high sciences” and politicized projects, and are not oriented to solving problems that concern private industry.

—Under pressure from different political and pseudo-political groups, some governments are establishing rules and regulations that are suppressing the innovation process. This is easily observed in EU countries where the cost of implementation and bureaucratic delays are much higher and longer then in the United States.

—The governments of many countries do not have clear strategies in regard to the macroeconomic parameters of R&D. This is especially valid in developing countries or countries in transition where a meager 0.1%-0.4% of their already low GDP is allocated to R&D. The self-organization of the industrial community may largely improve the actions of governments. In particular, the role of large professional organizations should not be overestimated if their influence is used properly and in a timely manner.

The following internal deficiencies were discussed and concluded at the joint meeting of the IUPAC Committee on Chemistry and Industry (COCI) and CHEMRAWN, the day after the forum:

• The scientific community—academe in particular—is only oriented toward the first part of the innovative process: invention. Often, when an industry approaches universities with the intention of implementing new processes, it finds that more research is needed (usually a long and costly process) to prove the invention's profitability.

• The scientific community is seeking research funding in “politicized” areas (e.g., the “climate warming” problem), while many important social and economic problems remain unresolved.

• The scientific community has established a pattern of “self support” when projects are competitively selected. This means that funding is not necessarily based on the merits of the proposal.

• The potential of R&D is decreasing around the world due to the effects of multinational companies; small groups of researchers are losing out to large companies in their search for funding. Large companies prefer to kill the competition in research instead of cooperating, although they very often use the creativity of small R&D companies. In addition, these large companies seldom subcontract with small research companies in the developing world.

• Process engineering, which is crucial to innovation implementation, is under-funded and funds are decreasing. In many countries this is due to budgetary difficulties, but in others it is because of underestimation by liberal politicians of the potential impact of innovation. However, it must be acknowledged that the unit cost of R&D is constantly growing mainly due to the need for expensive research instrumentation. Despite these cost barriers, examples at the forum showed that combination and new usage of existing equipment resulted in fruitful research advancement.

In 2005, “Innovation in Chemistry” will be the central theme for the IUPAC Congress. The CHEMRAWN Committee hopes that all relevant IUPAC bodies will actively participate in that conference. The forum plans to prepare “white papers” for dissemination at the Congress on the following crucial aspects of the innovative process: (i) Evaluation Methodology of the Assessment of the Innovative Project, and (ii) System of Establishment of the Technology Parks: University, Industry, and Government Role in Organization, Financing and Implementation of Innovative Processes. Collaboration with COCI and the IUPAC Committee on Chemistry Education will be developed.

For a more detailed account of the forum, please contact the author. The agenda and some of the materials presented at the event are available online.

Acknowledgements: J.A. Kopytowski joins Michael Droescher, chairman of CHEMRAWN XVI, and Parry M. Norling, chairman of CHEMRAWN from 1998 to 2003, in acknowledging each and every contributor to the forum, including Min Che Chon, Merion Evans, Stan Gembicki, Raymond Hamelin, Colin Humphris, Makoto Imanari, George Intille, Robert Jensen, Fiedor Kuznietzov, Patrick Moyna, Ikenna Oneyido, Alan Smith, and Ayhan Ulubelen.

J.A. Kopytowski <[email protected]> or <[email protected]> is a member and secretary (2004-2005) of the CHEMRAWN Committee and a member of the task group for CHEMRAWN XVI.

www.iupac.org/standing/chemrawn.html

www.iupac.org/projects/2003/2003-003-1-021.html

Page

last modified 30 August 2004.

Copyright © 2003-2004 International Union of Pure and

Applied Chemistry.

Questions regarding the website, please contact [email protected]

|